ColdBlock Technologies Inc. reveals game-changing sample digestion technology at PDAC

ColdBlock’s breakthrough came when it was able to reach temperatures of up to 1,000 degrees Celsius almost instantly

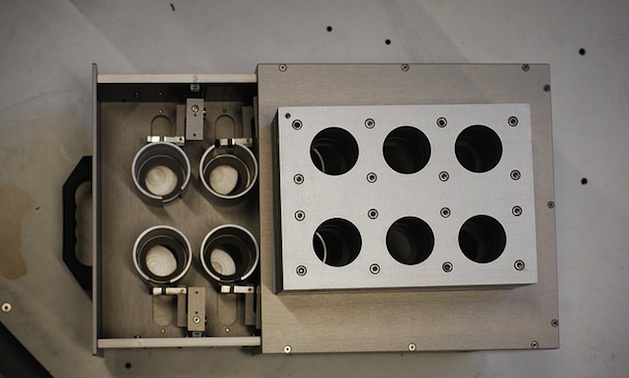

The ColdBlock sample digestion unit, which can process up to six samples at once. — Photo courtesy ColdBlock Technologies Inc.

Mississauga-based startup ColdBlock Technologies Inc. has unveiled a new sample digestion technology that looks to revolutionize the way mining companies and laboratories test ore samples. Not only does ColdBlock’s technology improve sampling accuracy, it also promises to slash the amount of time and money required and make the procedure far safer for both humans and the environment.

Conventional sample digestion techniques involve mixing powdered ore into an acid solution and then heating the solution until the solids are dissolved and an elemental analysis can be conducted. Not only is this process time-consuming, often taking several hours to complete, it also requires high volumes of perchloric acid and other hazardous reagents, which have to be vented using expensive fume hoods and other techniques. And seeing as conventional techniques are only capable of partial digestion, they’re not nearly as accurate as mining companies would like.

ColdBlock’s breakthrough came when co-inventors Ron Emburgh and Ravi Kanipayor realized that, rather than heating the acid solution, they could heat the sample particles instead using infrared radiation. This way, rather than be restricted by the boiling point of the solution, they were able to reach temperatures of up to 1,000 degrees Celsius almost instantly. Not only did this drastically reduce the time required for digestion, taking just 10 to 15 minutes in most cases, by using a ColdBlock—a proprietary combination of liquid coolant and fans—to prevent the acid solution from boiling off, they were also able to reduce the volume of dangerous reagents required and eliminate the need for perchloric acid altogether. Furthermore, the process provided total or near total digestion, greatly improving the accuracy of the elemental analysis.

Emburgh first got the idea for ColdBlock in 2009 when he was hired to do a marketing study for a manufacturer of conventional hot block and microwave sample digestion technology.

“I wondered why they kept hitting a glass ceiling," he said. "Each year, their business didn’t increase. I realized there was a real need for innovation in the industry, especially on the mining side. So I started to investigate ways to pick up the digestion speed.”

After Emburgh teamed up with Kanipayor to form ColdBlock, the fledgling company forged a unique partnership with government, academia and the private sector to help fund and support research and development of the technology. The team included: Brock University; the Research, Innovation and Commercialization Centre; the Centre for Excellence in Mining Innovation; the Natural Sciences and Engineering Research Council of Canada; the Ontario Centres of Excellence; and Barrick Gold Corp. After five years of research and development, ColdBlock is finally ready to go to market.

Emburgh believes the technology will have broad appeal to commercial labs that are looking for a competitive edge.

“Obviously, a big motivator for labs is productivity," he said. "They’re looking for better margins and lower costs so they can be more competitive. One of the biggest costs is infrastructure. If you walk into one of the big commercial labs on the mine side, you see an array of different technologies for sample digestion. There’s no one universal footprint. We believe ColdBlock is a viable alternative to all of the existing technologies out there. It’s a highly versatile technology that can be used for multiple elements, so you don’t need to multiply lab setups.”

In addition to reducing infrastructure requirements and operating costs, ColdBlock CEO Nick Kuryluk points out that by decreasing sample preparation and processing times, ColdBlock will also allow labs to dramatically increase the volume of samples they process each day. In addition, ColdBlock is portable and economical enough to be used on the mine or mill site as well, allowing companies to quickly test for elements of interest or monitor tailings to ensure their extraction process is running as efficiently as possible.

“This is truly a game-changing technology,” he said.

While the mining industry is ColdBlock’s first target, Kuryluk said mining is only the beginning.

“This is a platform technology that applies across a number of industries, including the environmental sector, pharmaceuticals and agriculture. We aspire to become a leading sample digestion technology for the mining industry and to expand into other industries in the near future.”

After unveiling its technology at the Prospectors and Developers Association of Canada (PDAC) conference in Toronto this March, ColdBlock will begin shipping product to labs in May. In the meantime, the company has launched a demonstration lab that allows mining companies to sample the technology for themselves.

To learn more about ColdBlock, visit www.coldblock.ca.