Cranbrook entrepreneur invents a solar and wind-powered construction light tower

Mike Hambalek is a machinist and inventor

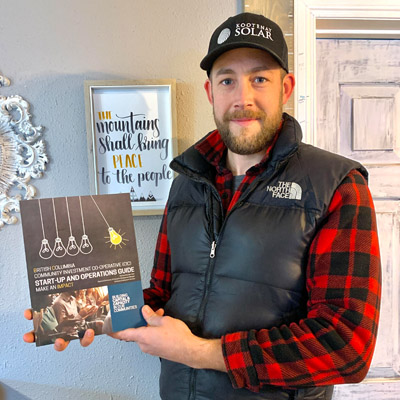

Mike Hambalek with Soleco's second generation solar and wind-powered light tower. — Kevin Miller photo

Mike Hambalek, owner of Caliper Machine and Hydraulics in Cranbrook, BC, recently had T-shirts made for his staff that give his tongue-in-cheek definition of a machinist: “Someone who makes s**t you can’t.”

Hambalek speaks with authority. Not only is he a machinist, he is also a serial entrepreneur who specializes in identifying problems his clients face and then inventing a solution. Although he tends to concentrate on products for the mining sector, Hambalek—who holds four patents—is involved in everything from solar-powered field washrooms to developing a military grade ATV that will protect Canadian soldiers from improvised explosive devices.

Hambalek’s latest project is a solar and wind-powered LED light tower designed for use in remote industrial locations, such as mines, road construction sites and the oil patch. As with his other inventions, this venture began with a problem in need of a solution.

The problem in question is the fact that large mining and oil companies spend up to $1 million a year in fuel costs to run diesel-powered halogen light towers. Not only are they expensive, but running diesel generators 24 hours a day is bad for the environment. Hambalek and his business partner Bob Frampton decided they could solve both problems at once by replacing the power-hungry halogen bulbs with LED lights and swapping out the diesel generator for solar panels and wind turbines.

Using off-the-rack components, Frampton had already cobbled together a prototype solar-powered light tower that he was using in the field.

“He had it running for two years and never used a penny of diesel,” Hambalek said.

Soleco's second generation solar and wind-powered light tower in transport mode. — Photo courtesy Mike Hambalek

Encouraged by his success, Frampton set off in search of someone with the manufacturing expertise to help him design a new and improved device from the ground up. That’s when he found Hambalek. Hambalek was so taken by the idea that he formed a subsidiary company with Frampton called Soleco Technologies, dedicated entirely to manufacturing the light tower.

Over the next 18 months, Hambalek and Frampton researched the market—and the competition—and polled prospective clients about what they desired in such a product. Then they sourced a manufacturer in China and went over there to personally supervise construction of a prototype. Although Hambalek prefers to manufacture locally whenever he can, in this case he said it made more sense to look offshore.

“They could build it from scratch in 20 days, because everything is manufactured there—the lights, solar panels, hydraulic jacks. If I had it made in Canada, it would have taken up to a year.”

The experience certainly gave Hambalek and Frampton second thoughts about having work done overseas, though.

“We had to babysit it the entire time,” Hambalek said.

Not only that, but when they finally got it back to Canada, they discovered much of the construction was sub-par, and they had to basically reengineer the product themselves. However, after working out the bugs over two generations of prototypes and finding a new Chinese manufacturing partner, they’re now finalizing construction of their third prototype, with plans to begin mass marketing it this spring. Once the light tower goes into production, Hambalek and Frampton will transfer manufacturing back to Canada so they can keep a better eye on quality control.

Mike Hambalek with Soleco's second generation solar and wind-powered light tower. — Kevin Miller photo

“My motto at Caliper is quality, service, expertise. I won’t sell something until it’s proven and tested,” said Hambalek.

Soleco’s third generation light tower features solar panels, twin wind turbines and a small backup diesel generator. The device provides 480 watts of power for 72 hours, and the batteries take 10 hours to charge. Two-thirds of that power comes from solar and one-third from wind. The solar panels, wind mast and stabilizers are all hydraulically powered, allowing for quick set-up and takedown. Unlike their competitors, Soleco’s solar panels also track the sun, making them up to 50 per cent more efficient. In addition to providing light, the towers can also be fitted with security cameras and Wi-Fi transmitters to create remote Internet hot spots.

Soleco has already had significant interest from several companies in Canada and as far away as Chile.

“Our goal is to have the cost be within the same bracket as a comparable diesel product,” Hambalek said. He believes Soleco’s devices will easily pay themselves within a year of operation due to fuel savings.

“They told us many times it wouldn’t work,” Hambalek said. However, for an irrepressible inventor and entrepreneur like him, such words aren’t the end of a dream; they’re just the beginning.