CoalTech turns coal mine waste into savings with newly launched coal pellets

Coal fines made green with new technology

CoalTech addresses the waste management challenges of mining. — Photo courtesy CoalTech

Everyone wants to be eco-friendly. Over recent years we’ve realized the impact our habits and technologies have made on our environment. CoalTech, an engineering company basing their research and development in South Africa, discovered a way to make our energy a little more green through coal agglomeration technology. CoalTech’s chairman, Filippo Fantechi, explained that its new product “generates more energy, more efficiently, cost-effectively, and addresses the waste management challenges.”

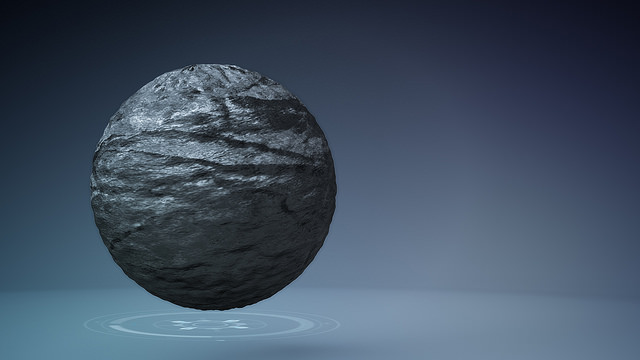

Coal mines inevitably produce coal fines, a wasteful byproduct that is difficult to dispose of. Their explosive qualities make them hazardous to both people and the environment. The top 10 coal-producing countries have an extreme excess of these coal fines that they cannot dispose of—upwards of 30 billion metric tons at the last estimated count. Not only are these coal fines hazardous when improperly disposed, but their disposal is costly.

“Coal fines, together with water, form part of the waste stream and are typically deposited in slurry ponds,” Fantechi said. “The development, maintenance and rehabilitation of the slurry ponds is another environmental cost.”

Not many realize that this expensive, wasteful byproduct could actually become valuable through proper recovery.

CoalTech’s innovative solution to minimize waste has just been launched for worldwide consumption. They have perfected the process of manufacturing usable coal pellets from the coal fines produced by coal mines, essentially turning waste into power. Power plants can use these coal pellets to generate energy, much like original coal. “It is a cleaner way to generate electricity,” Fantechi explained. With coal pellets, we can “reuse a byproduct to light houses, buildings, streets, provide domestic and industrial heat.” The coal pellets are flexible to suit any industrial furnace.

Aside from increased energy efficiency through the reuse of wasteful byproducts, CoalTech’s coal pellets help keep our environment clean and provide more jobs in all countries involved.

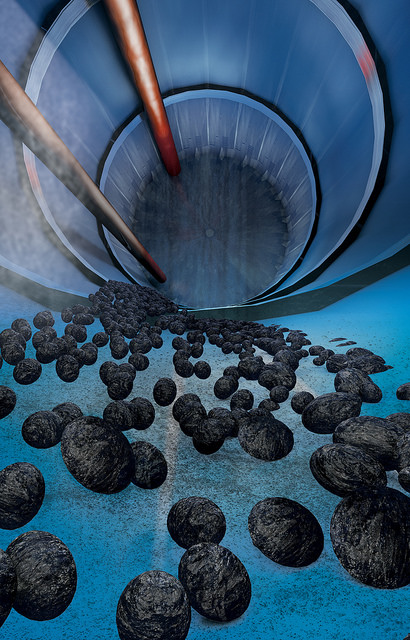

CoalTech's coal pellets are created in a large drum. The pellets are water-resistant, easily transported and flexible to suit any industrial furnace, and have the same combustion properties as the original coal. — Photo courtesy CoalTech

The lengthy list of benefits make CoalTech’s coal pellets a great choice of energy for all power plants. There are no changes in calorific values from the original coal; they are water-resistant, have the same combustion properties as the underlying coal, are easily transported and are flexible enough to power coal-fired plants across the globe.

Further, CoalTech’s research has shown that its innovative coal pellets extend the life of coal mines through the proper disposal and reuse of waste and even increase a mine’s performance by 20 per cent. Minimal waste—and minimal time spent trying to dispose of waste—is a sure-fire way to increase mining efficiency.

CoalTech's pellet production extends the life of coal mines, increases mine performance by 20 per cent and helps keep our environment clean. — Photo courtesy CoalTech

CoalTech isn’t the first company in search of a use for the coal fines and other waste materials from coal mines, but they are the first to succeed. “The coal pellets (of other attempts) could not withstand transportation or long-term exposure to weather,” Fantechi said. “The CoalTech pelletizing technology has been thoroughly tested and it is in operation with significant cost benefits.”

The pellets successfully met their first quality tests for industry standards at a pilot plant in South Africa by Bureau Veritas in March 2014. Since then, this pilot plant continues to push the boundaries of coal pellet development, producing astounding results. CoalTech’s coal pellets are now ready for commercial use in power plants worldwide.

“The product was launched at the Investing in African Mining Indaba event in South Africa this February,” said Fantechi. CoalTech has since received consumer reports of “excitement and endorsement for a long-expected solution to the coal fine challenge.”

CoalTech hopes its continuous development of the pelletizing technology will help it “secure solid partnerships,” minimize waste to maximize efficiency and expand globally.